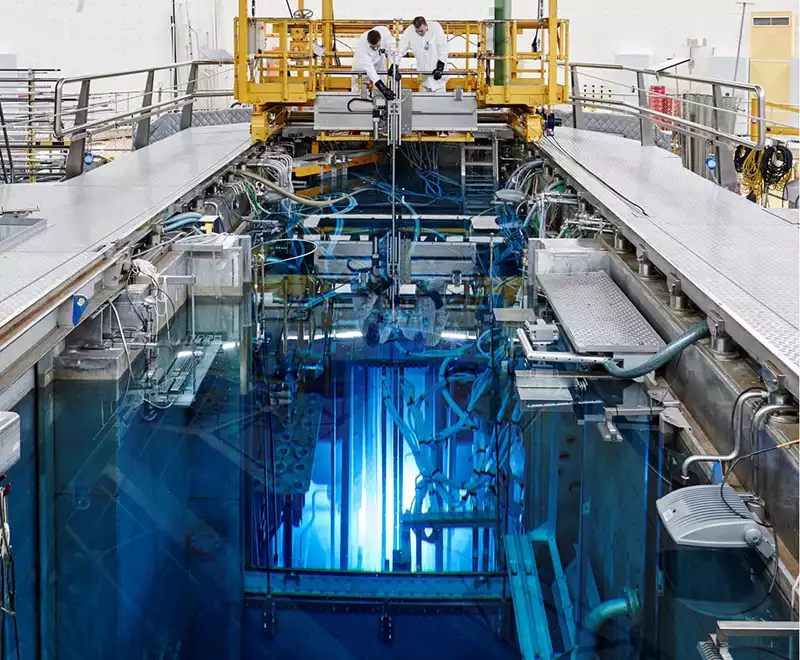

As of September 2020, there are currently 500 nuclear power reactors operating in the world today. The overwhelming majority of the reactors are light water reactors (LWR) of two types. Pressurized Water Reactors (PWR), where the water is heated to extremely high temperatures, but doesn't boil because the water is under pressure. The second is Boiling Water Reactors (BWR). BWRs actually boil the water, water is converted to steam, and then recycled back into water by a part called the condenser, to be used again in the heat process. Pressure is typically in the range of 75 - 150 times atmospheric pressure, requiring large reactor pressure vessels to house the reactor coolant, core shroud and reactor core.

There are reactors that use heavy water as a way to cool and control the nuclear reactions. These Pressurized Heavy Water Reactors (PWHRs) use water which is a chemically different form compared to “normal” water. Pressurized heavy water reactors (PWHRs) make up about 11% of the global nuclear fleet. By using heavy water these reactors are able to use naturally occurring uranium as fuel, rather than the enriched fuel needed for PWRs & BWRs.

The following examples are by no means an exhaustive list of the advanced reactors that are being developed or refined.

MSR’s are a class of fission reactors that have several designs and variations. These reactors use a fluid fuel in the form of molten fluoride or chloride salt rather than the solid fuel used in most reactors. These reactors are considered much safer than light water reactors, as MSR’s operate at high temperature, but low pressure. The low-pressure operation prevents any associated hydrogen explosions such as observed at Fukushima.

In the case of an emergency the molten mixture is designed to drain into a containment vessel and solidify as it cools. Unlike traditional nuclear reactors MSR’s can also be refueled while operating by adding more salt, which grows the in-core fuel salt volume. The growth eventually doubles the size of the the original fuel, allowing the start of another core. The operation during refueling and breeding of fuel allows for 24/7 uninterrupted sustainable energy.

In addition, a molten salt reactor produces noble gas radioisotopes that bubble out from the liquid fuel and that can be sampled and treated for radiopharmaceutical applications.

The Integral Molten Salt Reactor (IMSR) is reactor that produces energy for the Small Modular Reactor market. In addition to generating electricity at varying levels, it is able to provide thermal energy which can be transported up to three miles from the facility. This thermal energy can then be used for chemical production such as “green” hydrogen among others.

LFTR pronounced “lifter” Liquid fluoride thorium reactor. This reactor uses a thorium fuel cycle with a fluoride-based mixture of lithium fluoride and beryllium fluoride (FLiBE) molten salt. This mixture is both a coolant and solvent for fertile or fissile material.

Fluoride high-temperature reactor which uses solid uranium dioxide fuel (typically in TRISO-coated particles in a graphite matrix) cooled by a fluoride salt mixture, typically lithium fluoride and beryllium fluoride to achieve high operating temperatures.

A Pebble Bed Reactor uses Tristructural Isotropic particles (TRISO) as its fuel source. The reactor continuously refuels by adding fresh pebbles as the old ones are discharged and stored in dry casks on site without a need for cooling.

Small Modular Reactors are small, advanced reactors with a power capacity of up to 300 MWe per unit. A major benefit of SMR’s is they can be factory assembled and deliver for installation which saves time and construction costs and can be deployed incrementally to meet demand This works well in areas not suitable for larger nuclear plants and SMR’s can be installed into an existing grid or used remotely off grid.

Compared to pressurized reactors such as LWRs and BWRs SMRs rely on passive safety systems such as low operating pressure and low power.

SMRs have reduced fuel requirements with refueling every 3 to 7 years, with some designed to operate up to 30 years without refueling.

A subset of SMRs with power output up to 10 MWe. These reactors could be used as backup power, replacing diesel generators, or used in rural communities.